Plexi sheet is made available in desired sizes and shapes with plexi cutting processes. What is a plexi sheet with a shiny and transparent appearance? What is plexi cutting and how is it done? The answers are in our article

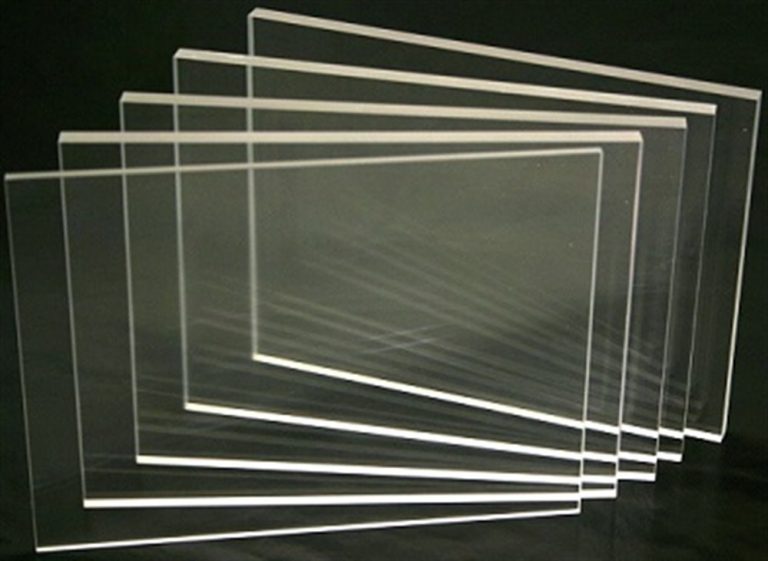

What is Plexi Sheet?

Plexi sheet is plexi material in various thicknesses and sizes. It is also known as “plastic glass” because of its transparent and shiny appearance. There are transparent, translucent or colored plexi sheets. Plexi sheets, a material resistant to different environmental and climatic conditions, can be used indoors and outdoors for a wide variety of products or purposes. Thermal conductivity is 20 percent lower than glass. Plexi sheet, which has high light transmittance, is six times more resistant to impacts compared to glass. When broken, the edges of the pieces are not sharp, so they do not cause injury.

Plexi sheet can be easily cut and drilled. It is easy to process for any design. It can be easily shaped at a temperature of 150 degrees. For this reason, it has a structure suitable for products of different designs in many different areas. It retains its shape given at high temperatures even when it cools down.

Plexi sheet is resistant to 80 degree heat. The combustion temperature is 400 degrees. 250 degrees flammable. The plexi market usually offers flat plexi sheets with a thickness of 1.5 to 3 mm.

What is Plexi Sheet Cutting and How to Do It?

Plexi sheet cutting is the cutting process for the design processes of plexi sheets. Plexi sheet cutting processes are done with plexi sheet cutting machines. Plexi laser cutting or CNC cutting is mostly used for plexi design, engraving or lettering applications. Plexi sheet cutting can be done in desired sizes and shapes. Plexi sizing processes can be applied free of charge within plexi laser cutting prices.

Cutting processes are applied on plexi cutting machines according to the product or project. Plexi sheet dimensions in the selected thickness and dimensions are adjusted according to the dimensions of the product. Plexi sheet cutting process is made with plexi cutting machine according to the product. Cutting processes can be made for plexi sheet in different sizes and colors.

High speed plexi cutting machine has hard metal or diamond teeth. Cutting with a circular saw can also be done with different tools or machines in small or large sizes. Plexi drilling is done with tapered drill bits.

Where is Plexi Sheet Used?

Plexi products obtained as a result of plexi sheet cutting processes are used in the following areas;

- Lighting products

- Advertising signs

- Showcase platforms

- Promotion stands

- Interior design

- Decoration

- Stair handrails

- Trabzans

- Table and coffee table accessories

- Display units

- Bathroom and kitchen products

- Decorations for marine vessels

- Boat and yacht windows

- Furniture accessories

- Souvenirs, ornaments

- Jewelry and gems

- Special design products

- Name tags and brochure holders

- Wish boxes

- Promotional products

- Desktop appliances

- Medicine stands

- Nuts containers.

Continue Reading

Similar Articles

Considering the differences between Plexiglas and acrylic, it would not […]

What is Acrylic? Acrylic is a transparent thermoplastic homopolymer. In […]

As COVID-19 continues its global onslaught, businesses are using sneezes, […]