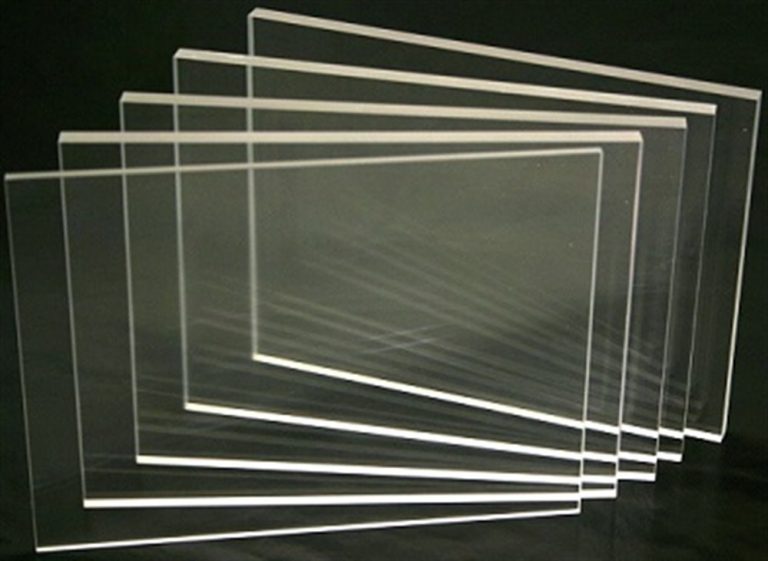

Plexi has become a solution tool for many sectors due to its useful structure. Many business areas where machines are used have also discovered the robust and easy-to-shape structure of plexi material. Plexi machine covers, which protect machines from external factors and provide a visually aesthetic appearance, offer very practical and fast solutions for machines.

Plexi Machine Parts

Plexi machine parts have become increasingly popular in recent years. The durable structure of plexi provides favorable solutions in many heavy or light sectors. The easily moldable structure of plexi is also utilized for machines exposed to external factors outdoors. Plexi machine covers are a new product that has become widespread in recent years. It is among the plexi machine parts designed to protect the machines.

Plexi machine covers, which can also be defined as boxes with plexi lids, can be easily adapted to machines of various sizes and designs. Various machine parts and machine guards made of plexi or plexiglass can be designed independently of the position of the machine. Plexi material, which covers the machine perimeter like a shield, can be produced as sharp-edged, oval, fanus or curved. In this sense, plexi laser cutting allows the design of all kinds of plexi machine parts.

Plexi machine covers are usually made of transparent white plexi material. Plexi machine covers can also be designed with different colors upon request. There are different shapes of plexi machine covers and parts, such as plexi fan cover or plexi curved cover.

What are the Benefits of Plexi Machine Covers?

Plexi machine covers are used in an unlimited range of fields such as industry and industrial sector, food, retail and automotive sector. So, what benefits do plexi machine covers provide for sectors?

Plexi machine parts or plexi machine covers;

– Protects machines from the negative effects of weather and moisture.

– Creates a protection shield for machines against impacts.

– The durable structure of plexi material is also suitable for machines used in heavy duty sectors.

– Its transparent structure allows monitoring the machine and indicators for possible interventions.

– Plexi, which can be easily shaped, can be designed according to all kinds of machines.

– Plexi cover production can be diversified according to the demand of enterprises.

– Plexi cover prices are much more affordable than other similar materials.

Continue Reading

Similar Articles

Considering the differences between Plexiglas and acrylic, it would not […]

What is Acrylic? Acrylic is a transparent thermoplastic homopolymer. In […]

As COVID-19 continues its global onslaught, businesses are using sneezes, […]